Ceramic Treatment - Diameter Ø125mm - (PB550)

Ceramic Treatment - Diameter Ø125mm - (PB550)

Regenerating directly integrated into a polishing foam with a diameter of 125 mm

Protective film composed of ceramic nanoparticles - High impact resistance

Fixes colors, brings radiance and shine

Water repellent and antifouling effect

Ceramic protection valid for 2 boats of 7 to 9 meters

The ceramic treatment is directly integrated into the polishing foam. One pulse against the shell and the product will be released.

Eco-friendly

An approved and certified action

Why use the Special Boat Ceramic Treatment from PadXpress?

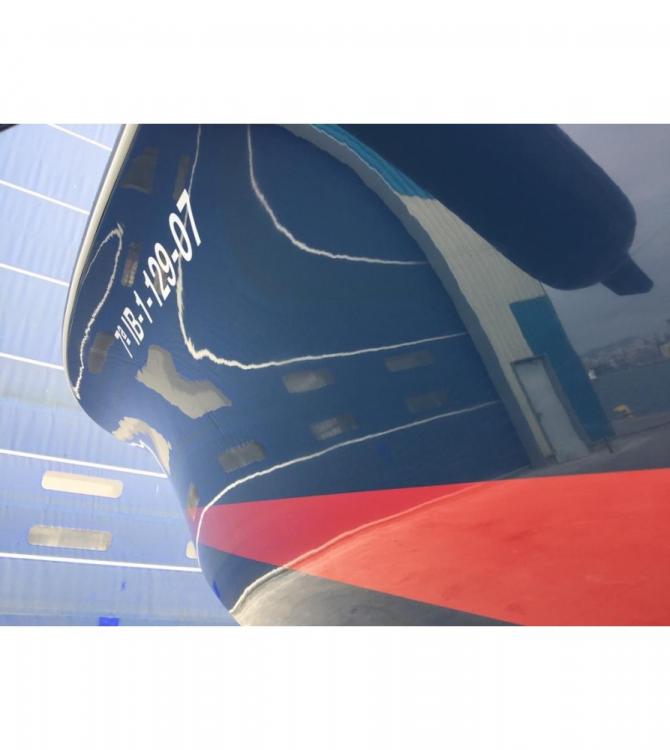

Over time the hulls of boats oxidize and lose their luster and shine, giving the impression of a boat in poor condition.

After having applied one of the PadXpress Nautic regenerants: the "special painted hull" (PB500) or the "special gelcoats" (PB800), to effortlessly renovate the hull of your boat, it is strongly recommended to use the Protection Ceramic. This protective film composed of silicon nanoparticles will protect your shell in a durable way.

It provides additional shine and shine (about 30% more) as well as a long-lasting protective film against impacts, blows, projections and thermal amplitudes that your shell undergoes. It is non-stick, resists impacts (docking, fender marks) and produces a real water-repellent effect.

Prerequisite

• The ceramic protective film is applied to a deoxidized surface and preferably without holograms. We advise you to use the Regenerating Paint (ref. PB500) or the Regenerating Gelcoats (ref.PB800) from PadXpress Nautic

• Check that the plate of your polisher is Ø125 diameter

Manual

1- Position the foam applicator on the polisher and select a maximum working speed of 1500 revolutions / min.

2- Place the applicator foam on the part to be polished, once it is clean and dry.

3- Apply vertical pressure on the foam (dry wrist) to release the product from its reservoir

4- Work with regular crossed movements, maintaining light pressure on the foam for good contact on the support.

5- Repeat the operation as many times as necessary depending on the surface to be treated.

6- Once the ceramic protection has been applied, leave to dry for approximately 30 minutes then polish with a cotton or micro-fiber cloth. For optimum results and a longer protection period, a second application of the ceramic protector can be carried out the next day.

A PadXpress Ceramic Protection foam is indicated to treat 2 boat hulls of 7 to 9 meters

Precautions for use

• Do not swallow, avoid contact with the eyes.

• Do not throw product residues into the sewer.

• Dispose of the applicator foam at an authorized collection center.

• Do not use the foam applicator for any purpose other than that for which it is intended.

• Keep out of the reach of children

Price: 149 € TTC